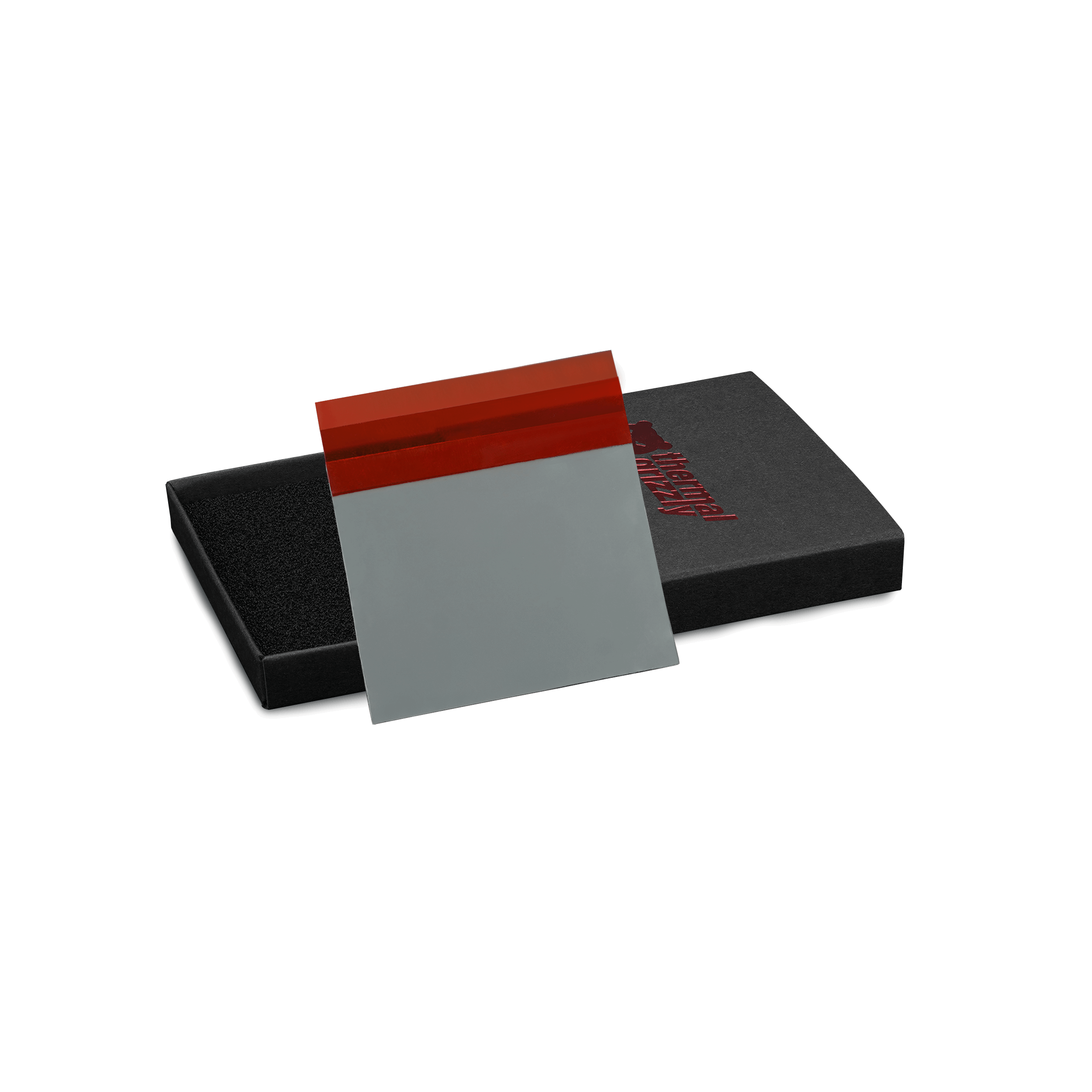

PhaseSheet PTM

Short information

- Outstanding thermal conductivity

- Consistently high performance

- Very long service life

- Versatile in application

- Not electrically conductive

- Easy to use

With phase change material against pump-out effect

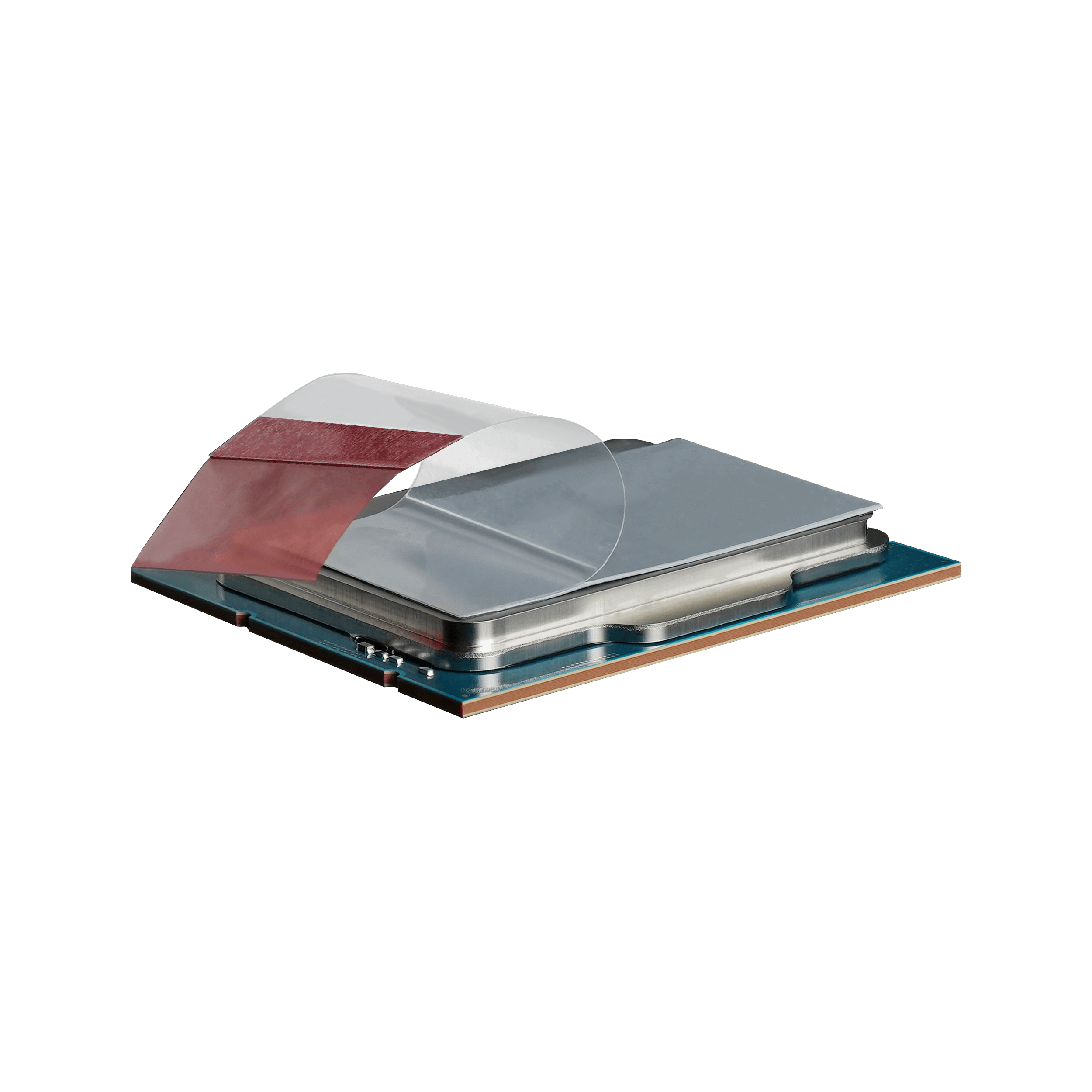

PhaseSheet PTM is a thermal pad that has been optimized for applications where maintenance cycles are subject to a high interval duration. It is more durable than traditional thermal conductive pastes, but not as durable as KryoSheet, for example, which is virtually maintenance-free. The maximum thermal conductivity of PhaseSheet PTM develops and stabilizes after around ten thermal cycles over 60 degrees Celsius.

The phase-change material on which the PhaseSheet PTM is based is solid at room temperature. The material only begins to liquefy at temperatures above 45 degrees Celsius. A high contact pressure of around 300-400N is required for optimum spreading of the liquid PhaseSheet PTM and thus the lowest possible layer thickness. Compared to traditional thermal paste, PhaseSheet PTM retains a very low viscosity in its liquid state and contracts again when it changes to a solid, so that the so-called "pump-out" effect is only very slight.

With the pump-out effect, the thermal paste is slowly pressed out between the heatspreader and the base plate of the CPU cooler, for example, because the heatspreader and the base plate deform (concave or convex) due to the temperatures under load and are returned to their original shape (straight) when they cool down.

Different materials, such as silicon and copper, have different linear expansion when heated. As a result, the pump-out effect is particularly pronounced when combining a copper cooler on a graphics chip, for example. Applications for the PhaseSheet PTM would therefore include, for example, replacing the thermal paste on older graphics cards or converting to water cooling.